Aluminium Cored Flux Brazing Wire

Price 200 INR/ Unit

MOQ : 10 Units, ,

Aluminium Cored Flux Brazing Wire Specification

- Application

- Brazing of aluminium and aluminium alloys

- Composition

- Aluminium with flux core

- Operating Temperature

- Up to 600C

- Material

- Aluminium

- Diameter

- 1.6 mm

- Flux Content

- 2.5% - 3.5%

- Melting Point

- 577C - 582C

- Coating

- Flux Cored

- Shelf Life

- 24 months

- Weight

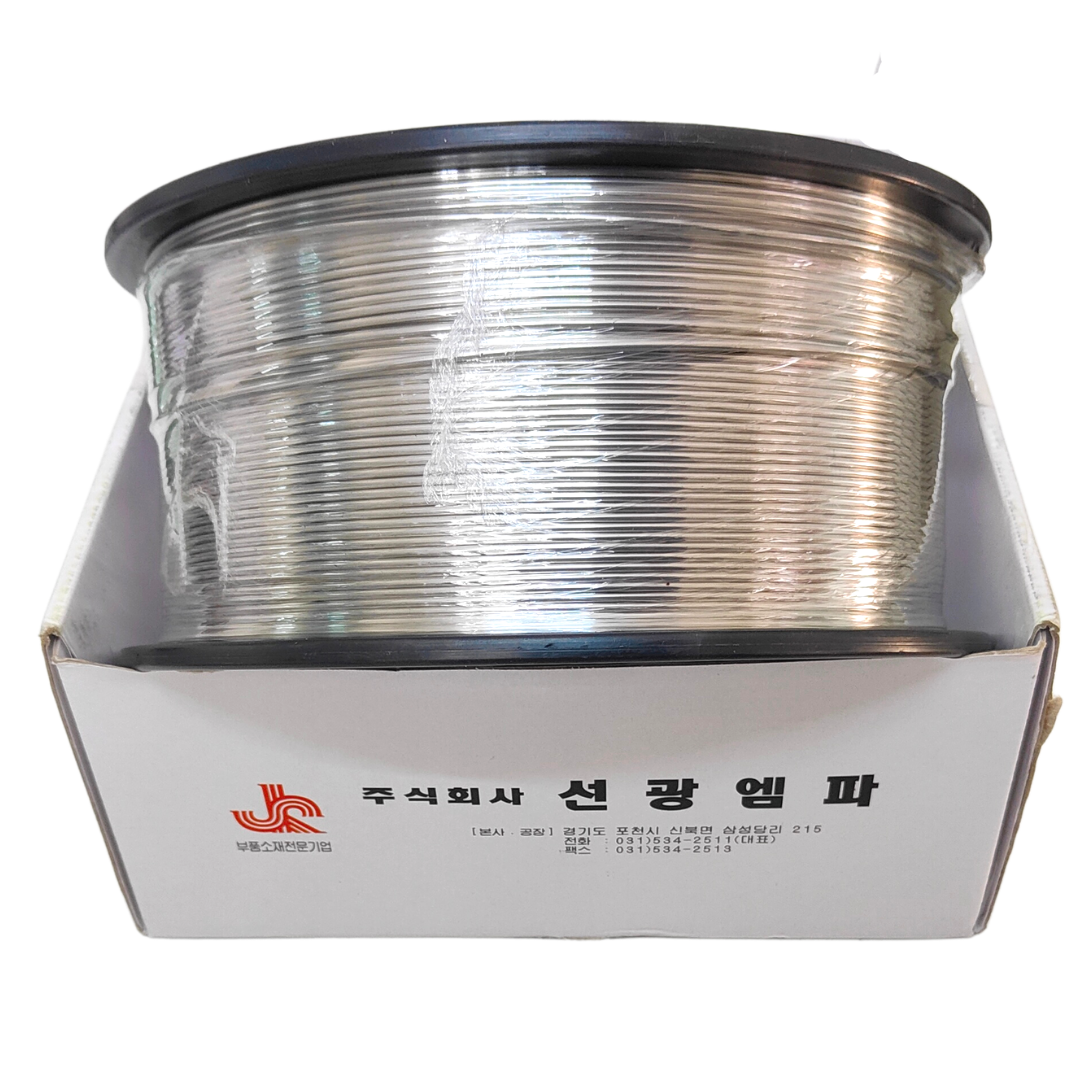

- 500g per spool

- Corrosion Resistance

- High

- Packaging Type

- Sealed plastic spool

- Wire Form

- Spool

- Density

- 2.6 g/cm

- Tensile Strength

- 110 MPa

- Color

- Silver Gray

- Standard

- AWS A5.10

Aluminium Cored Flux Brazing Wire Trade Information

- Minimum Order Quantity

- 10 Units, ,

- Supply Ability

- 100000 Units, , Per Day

- Delivery Time

- 7 Days

About Aluminium Cored Flux Brazing Wire

Grab the meritorious opportunity to secure our Aluminium Cored Flux Brazing Wire and elevate your brazing projects with incomparable quality. With a soaring tensile strength of 110 MPa and designed for exceptional corrosion resistance, this wire is perfect for demanding applications. Jump on this clearance offer for premium silver-gray spools-each weighing 500g and boasting a shelf life of 24 months. The flux-cored, 1.6 mm diameter wire meets AWS A5.10 standards, melting efficiently between 577-582C. Packaged on sealed plastic spools for maximum freshness, this product is essential for any importer, manufacturer, supplier, trader, or wholesaler in India looking to deliver outstanding results when joining aluminium and aluminium alloys.

Competitive Advantages & Applications of Aluminium Cored Flux Brazing Wire

This aluminium cored flux brazing wire offers superior corrosion resistance, a soaring tensile strength, and reliable performance in both industrial and commercial sites. Its meritorious conductivity and easy handling set it apart for repair, manufacturing, and fabrication of aluminium components. Widely utilized for HVAC, automotive, and structural applications, its flux core ensures strong, clean joints, while its sealed packaging maintains product integrity. Ideal for professionals seeking dependable, efficient brazing solutions.

FOB Port, Delivery, and Certification Details for Our Brazing Wire

Our premium aluminium cored flux brazing wire is delivered promptly from reputable Indian FOB ports. Packing & dispatch are executed meticulously, ensuring every sealed plastic spool reaches you in optimal condition. Delivery time is competitive, designed to meet urgent project needs. Each batch comes with certifications to guarantee quality, compliant with AWS A5.10 standards. Trust our service for professional supply, quick turnaround, and complete documentation, whether ordering locally or for export.

Competitive Advantages & Applications of Aluminium Cored Flux Brazing Wire

This aluminium cored flux brazing wire offers superior corrosion resistance, a soaring tensile strength, and reliable performance in both industrial and commercial sites. Its meritorious conductivity and easy handling set it apart for repair, manufacturing, and fabrication of aluminium components. Widely utilized for HVAC, automotive, and structural applications, its flux core ensures strong, clean joints, while its sealed packaging maintains product integrity. Ideal for professionals seeking dependable, efficient brazing solutions.

FOB Port, Delivery, and Certification Details for Our Brazing Wire

Our premium aluminium cored flux brazing wire is delivered promptly from reputable Indian FOB ports. Packing & dispatch are executed meticulously, ensuring every sealed plastic spool reaches you in optimal condition. Delivery time is competitive, designed to meet urgent project needs. Each batch comes with certifications to guarantee quality, compliant with AWS A5.10 standards. Trust our service for professional supply, quick turnaround, and complete documentation, whether ordering locally or for export.

FAQ's of Aluminium Cored Flux Brazing Wire:

Q: How should the Aluminium Cored Flux Brazing Wire be stored to maintain its shelf life?

A: Store the wire in its original sealed plastic spool packaging in a cool, dry environment. This helps retain its properties and ensures a shelf life of up to 24 months from the date of purchase.Q: What are the key advantages of using this aluminium cored flux brazing wire?

A: Key advantages include high tensile strength (110 MPa), superior corrosion resistance, a consistent melting point (577-582C), and efficient application in brazing aluminium and its alloys, meeting AWS A5.10 standards.Q: Where can this brazing wire be applied most effectively?

A: It is ideal for use in manufacturing, repair, and fabrication sectors, including HVAC, automotive, and general industrial applications where reliable aluminium-to-aluminium joints are required.Q: What is the process for using this brazing wire?

A: The wire is applied with a compatible brazing torch, operating at temperatures up to 600C. Ensure the surfaces are clean; then feed the flux-cored wire to create clean, strong bonds with aluminium components.Q: When can I expect delivery after placing an order?

A: Order dispatch typically occurs promptly. Delivery timelines may vary depending on destination, but we strive to deliver as quickly as possible from Indian FOB ports, with full packing and shipping documentation provided.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Aluminium to Aluminium Flux cored Brazing wire Category

Aluminium Flux Cored Injected Brazing Wire

Price 200 INR / Pack

Minimum Order Quantity : 6 Kilograms

Material : Aluminium

Aluminum to Aluminum Brazing Flux cored wire - SWAL 1240

Minimum Order Quantity : 5 Boxes

Material : Aluminum Alloy

Flux Content : Approximately 1015% by weight

Operating Temperature : 600C 650C

Diameter : 1.6 mm, 2.0 mm, 2.4 mm, 3.2 mm

Aluminium to Aluminium Brazing Flux cored wire spool - SU-TA200

Minimum Order Quantity : 5 Boxes

Material : Other, Pure Aluminium with flux core

Flux Content : Core filled, approx. 12% by weight

Operating Temperature : 650C 720C (Brazing process)

Diameter : 1.6 mm

Aluminum Brazing Flux cored

Price 490 INR / Box

Minimum Order Quantity : 5 Boxes

Material : Aluminum Alloy

Flux Content : 1015%

Operating Temperature : 600650C

Diameter : 1.6 mm

Send Inquiry

Send Inquiry