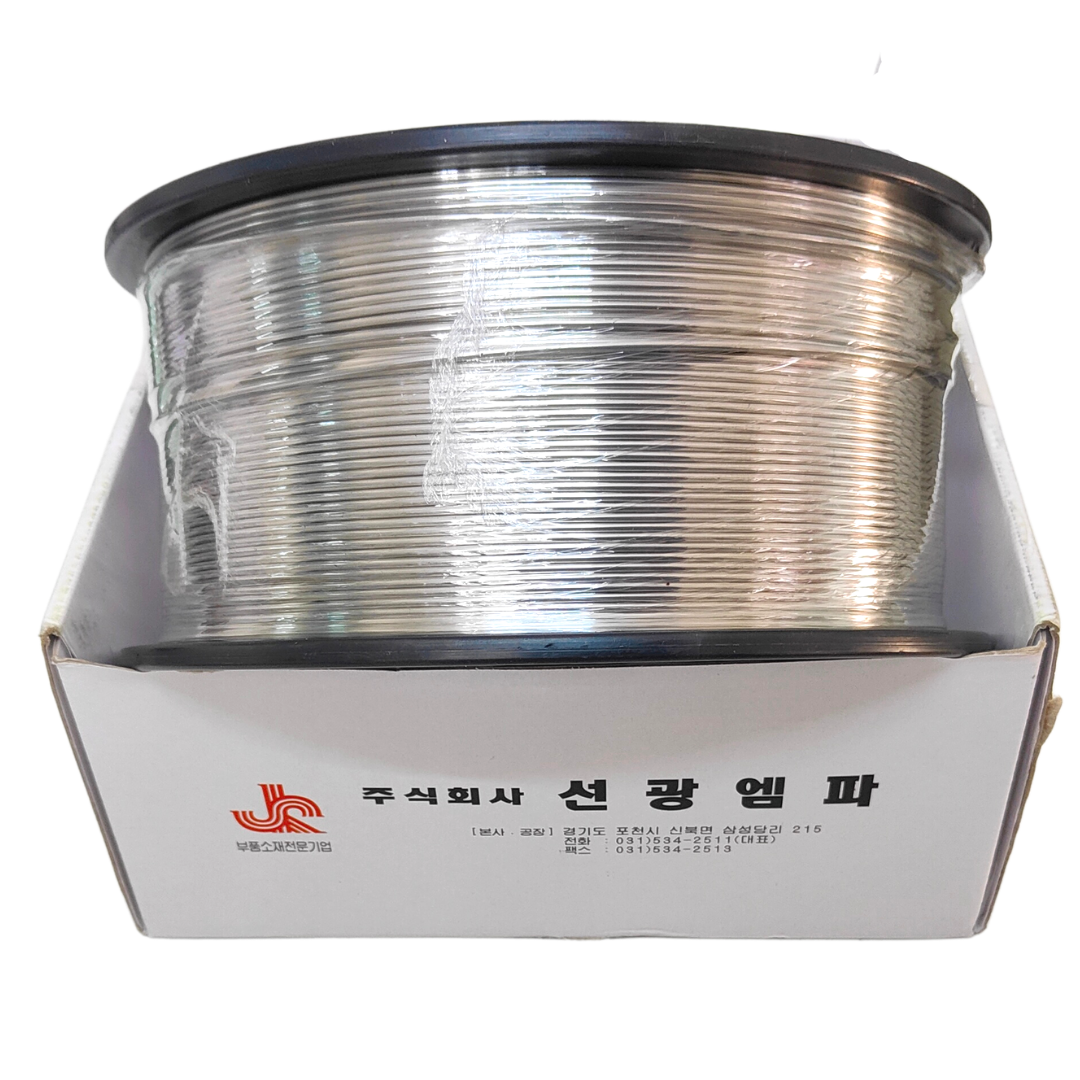

Aluminium to Aluminium Brazing Flux cored wire spool - SU-TA200

Aluminium to Aluminium Brazing Flux cored wire spool - SU-TA200 Specification

- Operating Voltage

- Not applicable; manual or torch based

- Application

- Aluminium-to-Aluminium Brazing

- Composition

- Aluminium core with proprietary inorganic flux mixture

- Operating Temperature

- 650C 720C (Brazing process)

- Material

- Pure Aluminium with flux core

- Diameter

- 1.6 mm

- Flux Content

- Core filled, approx. 12% by weight

- Melting Point

- 575C 585C

- Coating

- No external coating

- Wire Length

- Approx. 80 meters

- Spool Weight

- 500 g per spool

- Recommended Equipment

- Gas torch, air-fuel torch, or furnace

- Storage Instructions

- Store in dry, cool, non-humid environment

- Flux Type

- Non-corrosive inorganic

- Reactivity

- Low fume emission, no corrosive residue

- Color

- Silver-white

- Shelf Life

- 24 months in dry conditions

Aluminium to Aluminium Brazing Flux cored wire spool - SU-TA200 Trade Information

- Minimum Order Quantity

- 5 Boxes

- Main Domestic Market

- All India

About Aluminium to Aluminium Brazing Flux cored wire spool - SU-TA200

Aluminium To Aluminium Brazing Flux Cored Wire Spool - Su-ta200 Price: 490 INR / Box Company Details VIBHA ENTERPRISES Related Products More Products From ...

Efficient and Clean Aluminium Brazing

The SU-TA200 flux-cored wire simplifies aluminium-to-aluminium brazing, providing strong bonds with reduced preparation. Thanks to its advanced core-filled flux, users experience minimal fumes and no corrosive residue after brazing, promoting a clean work environment and ensuring long-term material integrity. Its pure aluminium composition paired with proprietary flux blend delivers consistent results.

Simple Storage and Extended Shelf Life

With a 24-month shelf life, the wire spool remains high-performing when kept in a dry, cool, and non-humid environment. The non-corrosive inorganic flux ensures that, even after prolonged storage, the wire retains reliable brazing properties without the risk of external coating breakdown or moisture absorption.

FAQs of Aluminium to Aluminium Brazing Flux cored wire spool - SU-TA200:

Q: How do I use the SU-TA200 flux-cored wire for aluminium-to-aluminium brazing?

A: To use the SU-TA200, clean the aluminium surfaces thoroughly, then apply heat using a gas torch, air-fuel torch, or furnace. Feed the wire at the joint area once you reach the optimal brazing temperature (650720C). The core flux will activate and support smooth, clean filler flow, ensuring a secure bond.Q: What is the main advantage of using a flux-cored wire with non-corrosive inorganic flux for brazing?

A: The main benefit is that it produces minimal fumes and leaves no corrosive residue after brazing, eliminating the need for post-braze cleaning and reducing the risk of joint degradation over time. This leads to a more efficient and cleaner brazing process.Q: When should I consider replacing the wire spool?

A: Replace the wire spool once it reaches its 24-month shelf life or if there are visible signs of moisture damage or corrosion, as these may affect performance and bond integrity during brazing operations.Q: Where should I store the SU-TA200 wire spool for optimal shelf life?

A: For best results, store the spool in a dry, cool, and non-humid environment, away from direct sunlight and moisture. Proper storage ensures the flux and aluminium wire retain their brazing efficiency and longevity.Q: What materials and equipment are recommended for using this brazing wire?

A: This flux-cored wire is specifically for aluminium-to-aluminium applications. Its compatible with manual gas torches, air-fuel torches, or a furnace; electrical or voltage-based process equipment is unnecessary.Q: What is the typical process temperature and melting point range for this product?

A: The brazing process using this wire generally occurs between 650C and 720C, while the wire itself melts between 575C and 585C, allowing a controlled, reliable bond to form at the joint.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium to Aluminium Flux cored Brazing wire Category

Aluminium Flux Cored Injected Brazing Wire

Price 200 INR / Pack

Minimum Order Quantity : 6 Kilograms

Material : Aluminium

Aluminum to Aluminum Brazing Flux cored wire - SWAL 1240

Minimum Order Quantity : 5 Boxes

Material : Aluminum Alloy

Melting Point : 575 610C

Operating Temperature : 600C 650C

Flux Content : Approximately 1015% by weight

Flux Cored (Injected) Aluminium to Copper Brazing Wire

Price 200 INR / Unit

Minimum Order Quantity : 10 Units

Material : Other, Aluminium

Melting Point : 590C 610C

Operating Temperature : Ambient to 620C

Flux Content : Core injected

Aluminum Brazing Flux cored

Price 490 INR / Box

Minimum Order Quantity : 5 Boxes

Material : Aluminum Alloy

Melting Point : 577610C

Operating Temperature : 600650C

Flux Content : 1015%

Send Inquiry

Send Inquiry